Re.Cycle processes commingled recycling through our Material Recovery Facilities

Re.Cycle develops, operates and maintains our industry leading Material Recovery Facilities (MRFs) which process 'yellow bin' household collected material across Australia.

Our key projects include Australia's newest state-of-the-art Adelaide SMRF and Australia's leading education facility at the Canberra MRF, among many more. This advanced technology is made possible through our experienced design team, RDT Engineering, who draw on international standards for the newest innovation and combine that with local Australian knowledge. Our facilities target an impressive 90%+ diversion from landfill, in order to create a more resilient recycling industry for all of Australia.

Re.Cycle processes kerbside co-mingled waste to recover and effectively extend the life of materials into products such as Cardboard, Mixed Paper, Ferrous metals, Non-ferrous metals, HDPE, PET Plastics and Glass.

Project

The Award-Winning Southern Adelaide MRF

The SMRF, located at Seaford Heights, South Australia, is a jointly-owned Material recovery Facility by Re.Group and the Southern Region Waste Resource Authority (SRWRA). It is the proud recipient of the 2022 Waste Innovation Awards 'Outstanding Facility of the Year'. The joint venture aims to create a more resilient recycling sector for all of South Australia, with a 20-30 year operating term. The site was commissioned in July 2021, an impressive feat considering the ongoing obstacles of the Covid-19 pandemic.

Who does this facility service?

The facility receives and processes materials from the household yellow bin collections for City of Onkaparingka, City of Marion and City of Holdfast Bay, as well as other councils including Campbelltown City Council and other commercial customers.

How many tonnes are processed at the MRF?

The facility has the capacity to process 70,000t/annum.

What products are created at the MRF?

The facility produces high quality recyclates including paper, aluminium, 5 grades of plastic and glass.

What technology is used at the MRF?

Technology at the site includes 7 optical sorting units with two quality control robots. The robots utilise artificial intelligence to sort recyclable materials to a 95% efficiency rate. They can be programmed to sort a particular material type. The software then transforms the material on the recycling lines into valuable data using computer vision to distinguish features much the same way as the human eye. Impressively, the robot AI can distinguish material in piled, non-singulated waste and rapidly learns to recognise consumer product branding and changes.

The AI maintains full awareness of all material that passes through the recyclable stream, even if it is not programmed to target that material. This software allows the robot to learn from experience and have allowed the system to identify the materials including HDPE, PET, aluminum, Tetra pack and more. The new SMRF robots nearly double the average pick rate, improve efficiency and increase the safety of our site.

How does Re.Group support the local community?

Re.Group operates the MRF with a focus on the local community. The team at the SMRF is led by Site Manager, John Kathiniotis, a long-time local from Adelaide. He draws on his impressive background in manufacturing to seamlessly operate the MRF.

Re.Group reached out to the local community to put together the 19 ground staff, who were selected via a thorough hiring process. Team members put their hand up to take on roles within the facility that best suited their existing skillset. Further training was then provided to ensure a consistent approach to the new technology.

Project

Townsville MRF

The Townsville MRF provides recycling services for Townsville City Council since commissioning in July 2017. Re.Group operates the MRF with a focus on creating local economic benefits.

Who does this facility service?

The facility processes the total co-mingled recyclables from 'yellow bin' collections from North Queensland's 192,000 residents.

How many tonnes are processed at the MRF?

The facility has the capacity to process 25,000t/annum, underpinned by 15,000t/annum of co-mingled recycling material from Townsville City Council, neighbouring councils and local businesses.

What products are created at the MRF?

The facility produces high quality cardboard, ferrous metals, mixed paper, non-ferrous metals, glass sand, HPDE and PET.

What technology is used at the MRF?

Technology at the site includes Alchemy SureSort optical sorters for plastics separation and a full glass sand circuit with dryer.

What does this MRF bring to the local community?

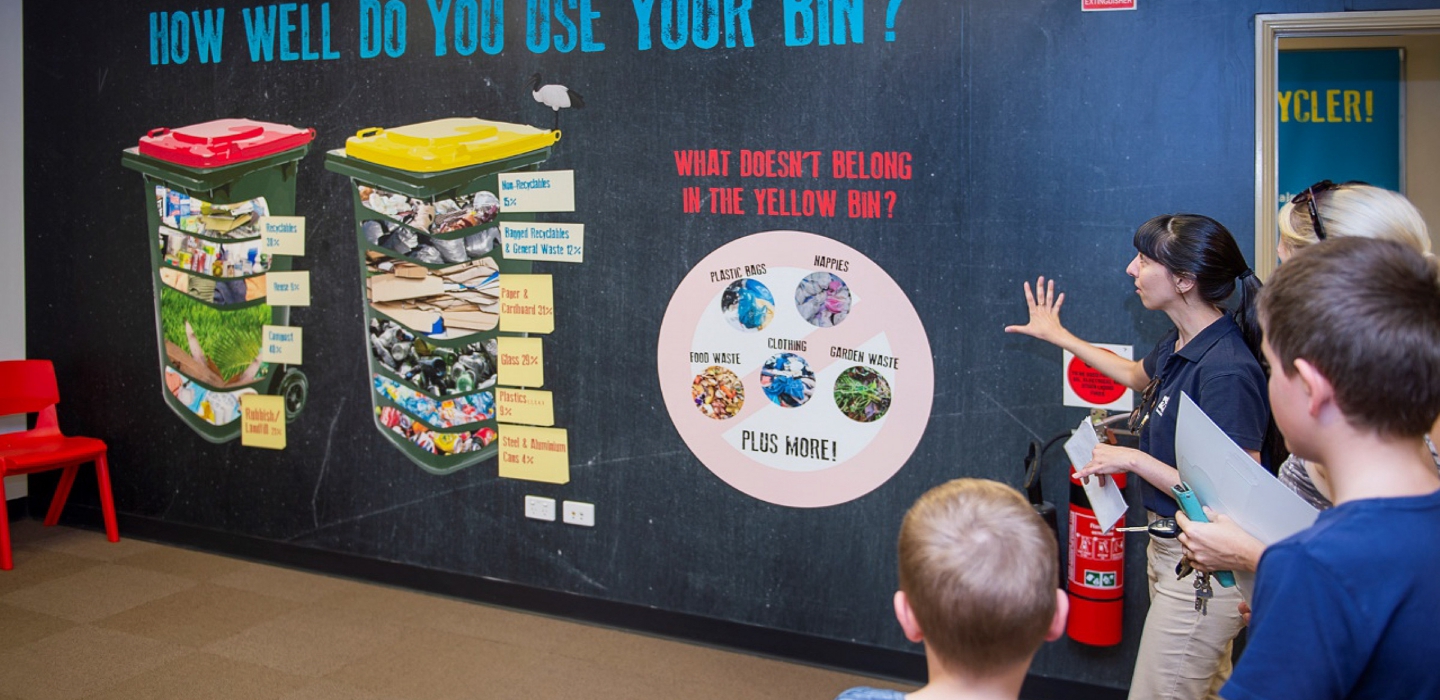

The Townsville MRF has an inbuilt education facility that encourages locals to take control and responsibility of their recycling practices. Re.Group and Townsville City Council still accommodate tours for the locals today.

Re.Group Services

Re.Group is actively delivering resource recovery services from mixed waste and source-separated recycling streams. We aim to provide clarity and efficiency with our communication and approach.

Our wide range of services allow us to provide an integrated approach where necessary and incorporate best practice equipment and systems sourced from leading international providers with a proven track record.